Heat Barrier Hat (HBH™)

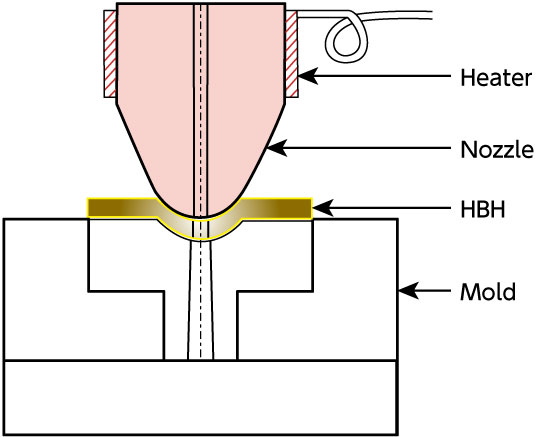

Insulate the molding machine nozzle and mold!

HBH™ insulates the molding machine nozzle and mold,

resolving problems in resin molding.

Insulate the molding machine nozzle and mold!

HBH™ insulates the molding machine nozzle and mold,

resolving problems in resin molding.

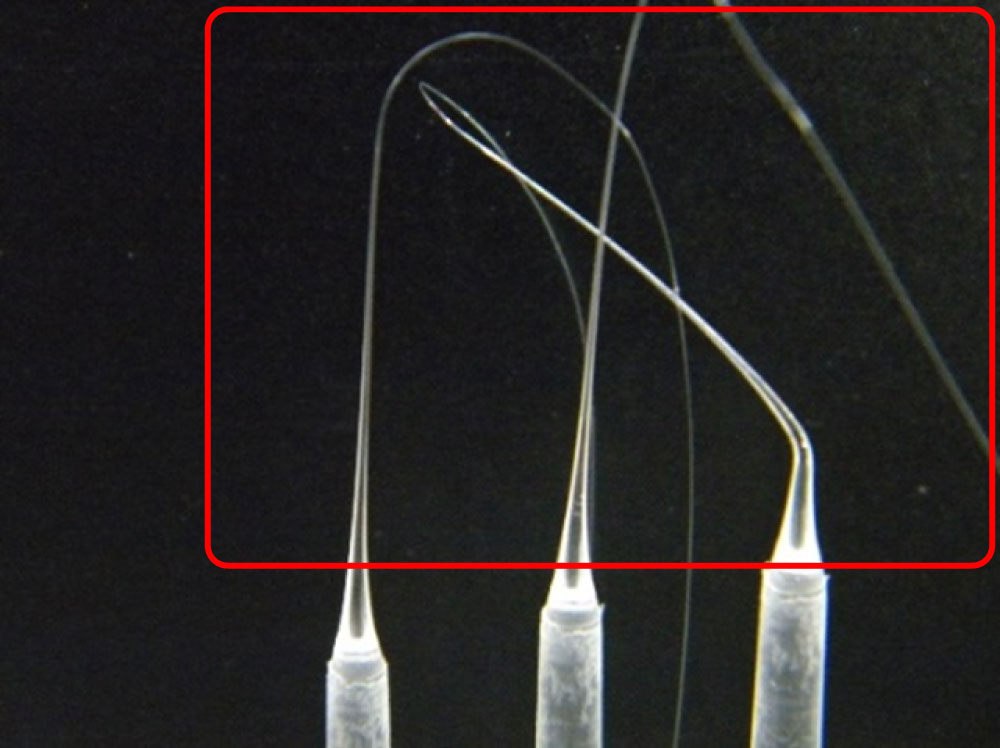

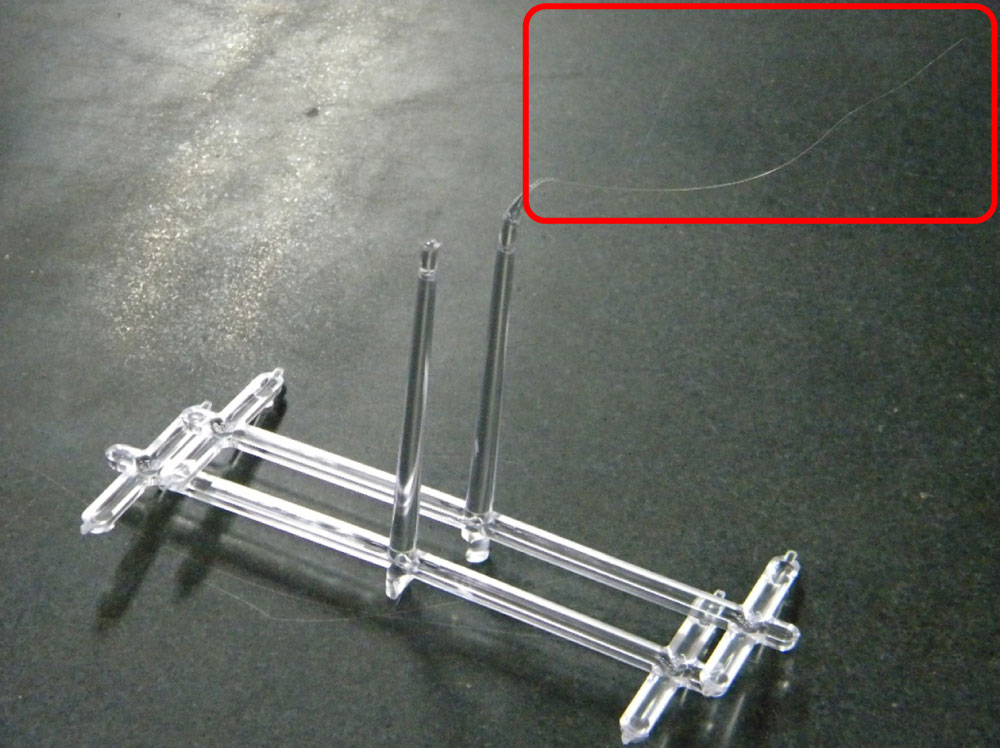

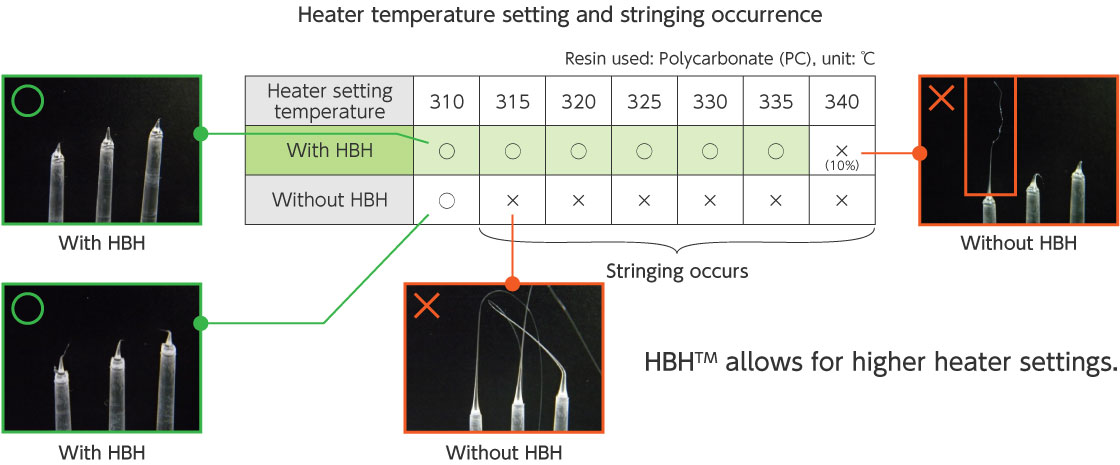

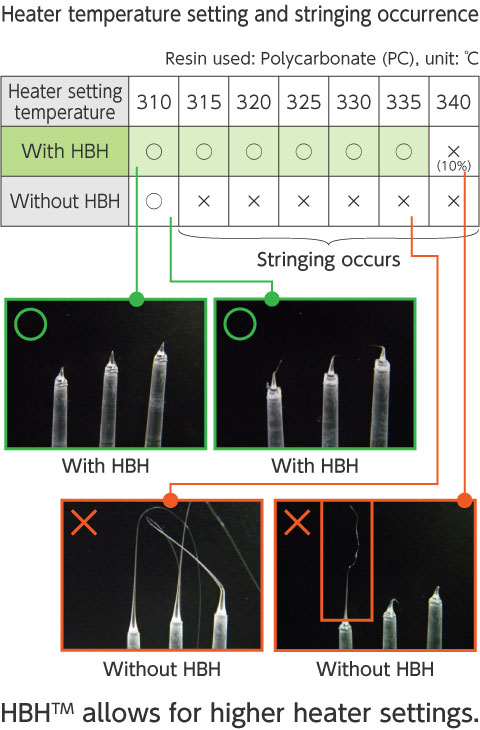

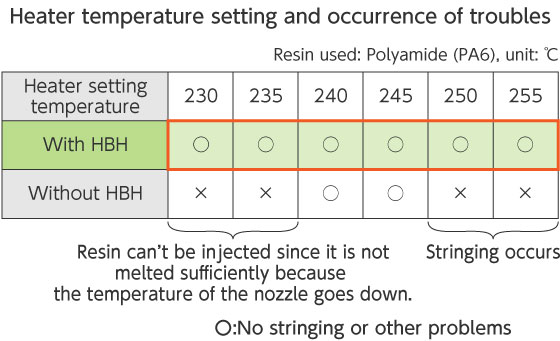

Stringing is a common inferior mode that occurs during resin injection molding, when incomplete solidified resin forms thread-like burrs when the product is removed.

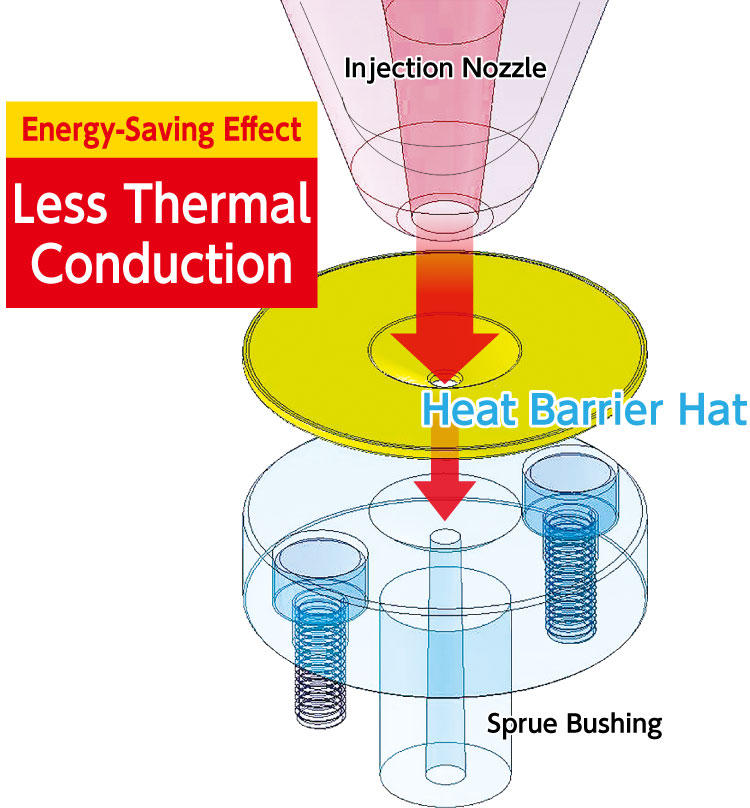

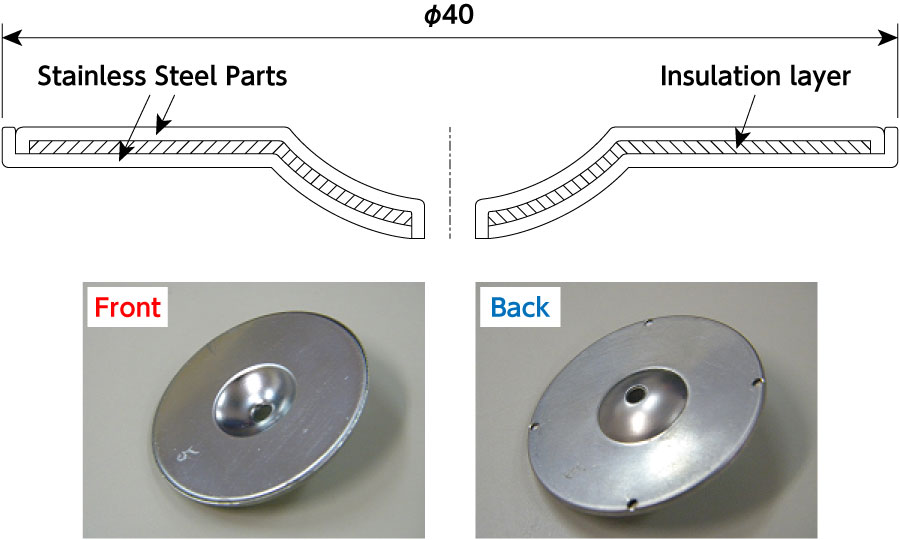

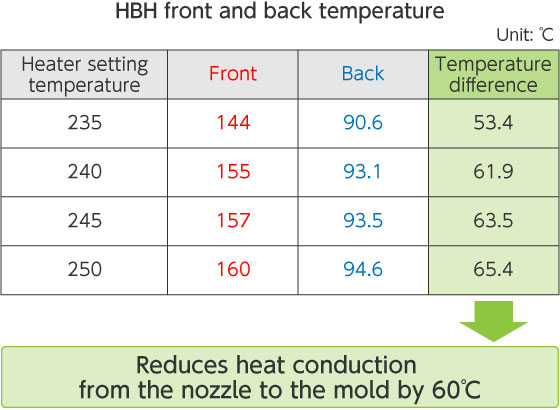

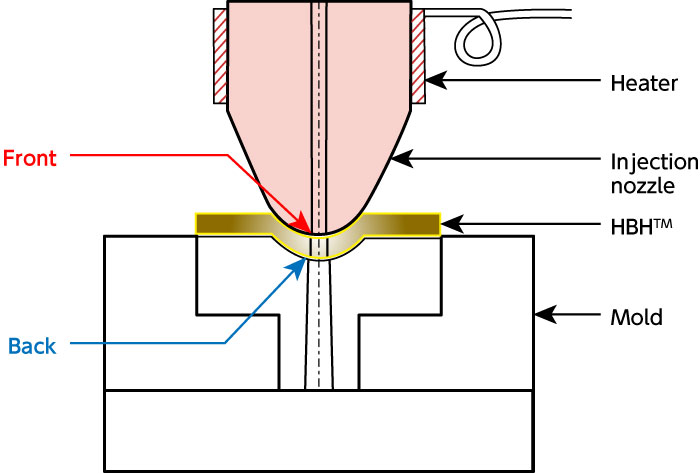

HBH™ (Heat Barrier Hat) is a jig that insulates the heat between injection nozzle and Mold.

Examples

Product A(Φ17.5mm×t 6mm, PP)

Product B(47mm×4mm×1mm, PP)

Product C(Φ17.6mm×t 5mm, PBT)

Molded Products

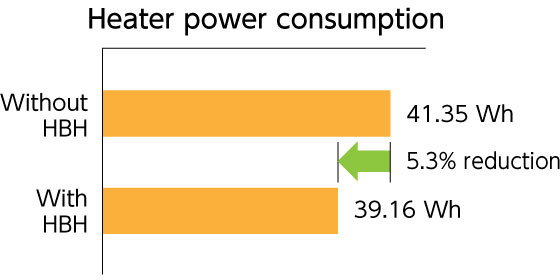

(41.35Wh − 39.16Wh) × approx. 25 yen (Kansai Electric Power Co., Inc. A 1kWh unit price for metered lighting) × 7 (H/day) × 220 (days/year)

= Annual electricity bill reduction of 84,315 yen per unit

The heat of the nozzle is not transferred directly to the mold. So the nozzle heater temperature setting can be lowered, resulting in energy cost savings.

| Resin | WORKING EXAMPLES (comments given by molding manufactures) |

|---|---|

| 46 nylon | "To prevent stringing, the nozzle was moved backwards after each molding. By using a HBH, it became possible to perform continuous molding while keeping the nozzle in close contact with the mold." |

| 6 nylon | "To prevent stringing, we had no choice but to lower the nozzle temperature setting. By using HBH, the nozzle heat is not absorbed by the mold, so we were able to raise the temperature setting to the desired temperature. As a result, there was no risk of insufficient resin filling (short), and molding quality was stabilized." |

| POM | same as above |

| 66 nylon | "The nozzle temperature setting could be lowered, which saved energy and stabilized molding quality." |

| ABS | "The molding peak pressure was reduced by 0 to 20 MPa. The heat from the nozzle was no longer absorbed by the mold, improving the fluidity of the resin. As a result, the range of molding conditions that can produce quality products has widend" |

| AS | "By lowering the nozzle temperature, we were able to prevent discoloration of the resin." |

| PP | There was always stringing at the tip of the sprue. By using HBH, stringing disappeared and the occurrence of non-conformance was greatly reduced. A major molding manufacturer. Total purchases: 186 units. |

| "Conventionally, in order to prevent stringing, it was necessary to cool the mold sufficiently before opening it, which made it impossible to shorten the molding time. By using HBH, stringing can be suppressed and the molding time can be shortened." |

HBH can be used for many types of resins, including nylon.

Effects vary depending on the resin specifications and grade.

etc.

(For examples)

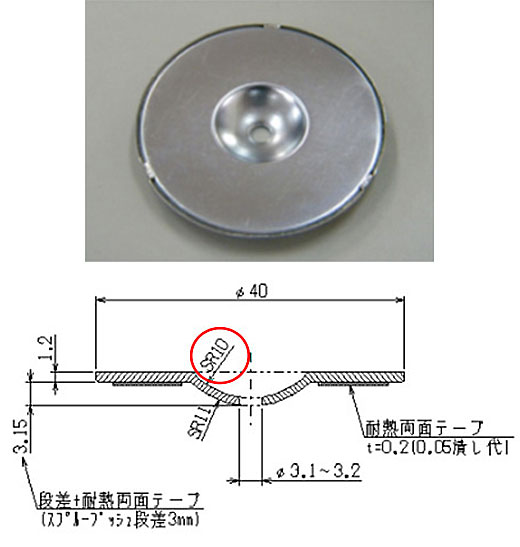

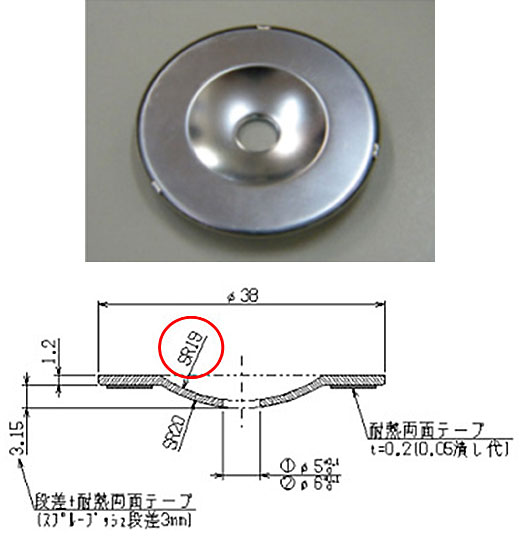

In addition to the HBH™ (standard product) for molding machine nozzles with a radius of 10 mm, there is also the HBH™ (custom-made product) for molding machine nozzles with a radius of 19 mm.

SR10 (standard product)

SR19 (custom-made product)

Awards